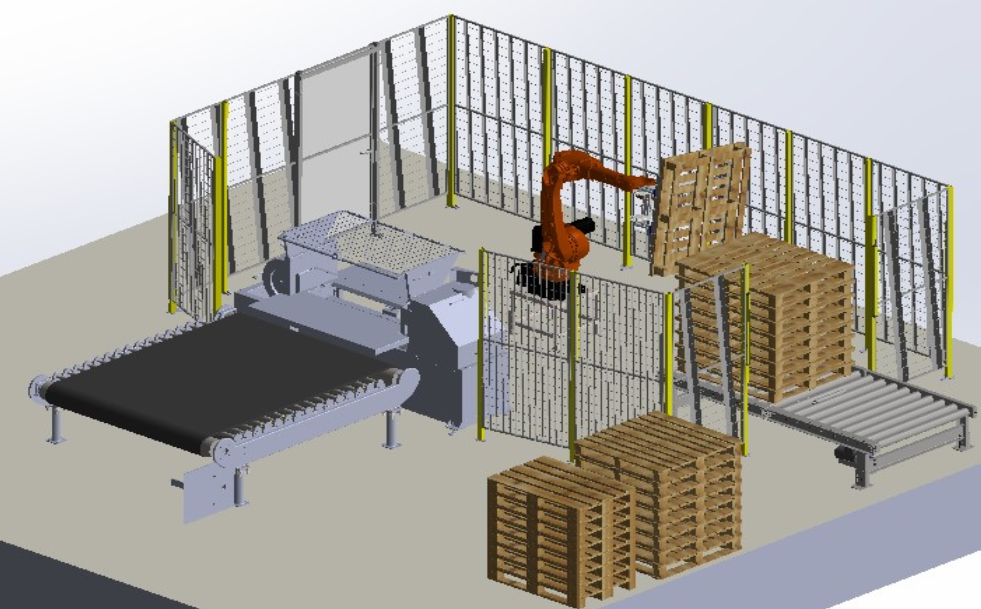

Robot dismantler paller cell

.

**Technical-Commercial Description: Robotized Cell for Partial Pallet Disassembly (EUR PRS7 and PRS9 Types)** The **robotized pallet partial disassembly cell** is designed to provide an automated, efficient, and safe solution for the disassembly process of wooden pallets of the EUR PRS7 and PRS9 models. This cell optimizes the operation through the integration of advanced technology, standing out for its ability to manipulate and disassemble pallet components with high precision and reliability. ### Main Components: 1. **Entry Roller**: Acts as the initial station in the process, where pallets are positioned stably for processing. The roller is equipped with systems that allow proper feeding of pallets into the working system, ensuring their alignment and smooth access without interruptions. 2. **Manipulator Robot with Suction Plate Clamp**: A high-capacity industrial robot, designed to manipulate the components of wooden pallets with precision. The robot is equipped with a suction plate clamp, allowing it to securely hold the wooden pieces to proceed with the disassembly efficiently and in a controlled manner. The clamp uses suction technology for a secure grip without causing damage to the materials. 3. **Alos Industrials D150A Pallet Disassembler**: The D150A disassembler is a robust and efficient machine specifically designed for disassembling wooden pallets. The machine is capable of quickly and precisely removing boards and other pallet components, facilitating their subsequent recycling or reuse. 4. **Conveyor Belt**: After the disassembly process, the resulting material is transported via a conveyor belt that efficiently collects and moves the wooden components to the exit area. This belt enables continuous material flow, optimizing space and facilitating further handling. 5. **Safety Enclosure**: The entire robot work area is protected by a safety enclosure, ensuring that the operational area is isolated and secure for operators. This enclosure includes an access door for maintenance and supervision, guaranteeing worker safety at all times. 6. **Safety Curtain at the Entry Roller**: To prevent any risks, the cell includes a safety curtain that delineates the pallet entry zone. This curtain acts as an additional barrier, preventing unauthorized or accidental access to the robot’s work area, providing a completely safe environment for operations. ### Key Features: - **High Automation**: The cell allows for a fully automated process, reducing manual intervention and increasing productivity. - **Comprehensive Safety**: The design of the cell includes advanced safety systems, such as perimeter enclosures, safety curtains, and access controls, minimizing operational risks. - **Efficiency and Precision**: The manipulator robot with suction plate clamp and the D150A disassembler work complementarily to ensure efficient disassembly without damaging materials. - **Space Optimization**: Thanks to the conveyor belt system, the cell makes the most of available space, ensuring continuous material output and avoiding bottlenecks in the process. ### Benefits: - **Reduction of Operational Costs**: The automation of the disassembly process reduces the need for human intervention, optimizing work times and increasing operational efficiency. - **Improved Safety**: With protection systems and safety enclosures, a risk-free work environment is ensured, complying with industrial safety regulations. - **Increased Productivity**: By minimizing downtime and reducing potential human errors, the cell allows for a faster and smoother workflow. - **Flexibility in Handling**: The cell can work with different types of EUR PRS7 and PRS9 pallets, adapting to various production needs. This robotized cell is an ideal solution for companies seeking to optimize their wooden pallet disassembly process, improving efficiency, safety, and productivity in their facilities.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.